AF Froth Pump

Product Parameters

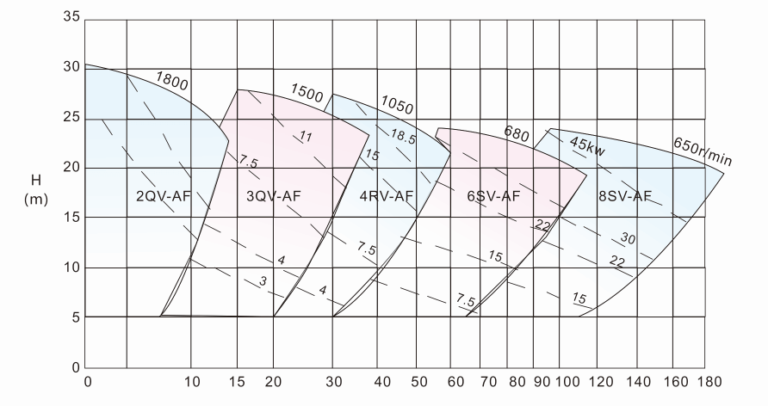

■ Flux:Q=10~5000(m³/h)

■ Head:H=20~120 (m)

■ Rotating speed:n=490~2900rpm

■ Proportion:γ ≤1

■ Temperature:T=0~120℃

■ Caliber:50~350m

Forth Pump Features

■ AF froth pumps are our company newly designed & developed products based on the advanced technology from home and abroad. Being popularized and promoted; now they are widely used in metallurgical industry, mining sector, coal ore, and chemical engineering to handle abrasive and corrosive slurries with foam and froth. When operated, AF pumps can effectively eliminate foam and froth in slurry and will also function properly even with inadequate feeding slurry, thus making them the ideal choice for delivering foam slurries, esp. in the flotation process.

■ A simple pump system layout allows for easy installation.

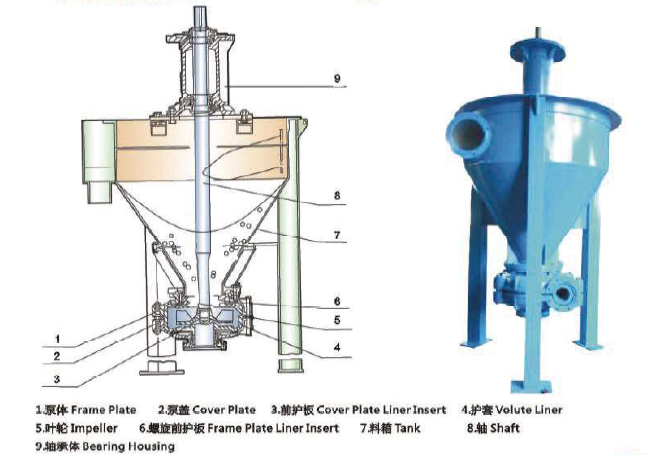

■ Transmission parts of this submersible pump are interchangeable with those of AF series. Installed above the bearing assembly is a motor mounting base or support frame. Flexible coupling or V-Belt is used to connect the motor shaft and the pump shaft. Pump shaft speed is easily adjusted by changing the grooved pulley so as to suit the varying pumping applications.

■ The hopper features a steely structure, complete with the tangential inlet and overflow box. The overflow box can easily send the excessive slurry back to the recycling tank. The tangential inlet allows the frothy slurry to enter into the froth pump while separating the air out of the slurry.

■ The pumping unit is interchangeable with the AH series. According to the kind of medium to be pumped, we can use metal, rubber, or other non-metallic materials to make the wet-end parts of this froth pump.

AF Forth Pump Material

■ The flow passage parts shall be made of Cr26 anti-wear material, or cr30, cd4mcu anti-wear and corrosion material and other general anti-wear materials according to the transmission medium.

■ Pump body, pump cover, bracket and other supporting parts: gray cast iron

Working Condition

■ They are designed for handing abrasive or corrosive alurry in the metallurgical,mining,coal,power,building material and other industral departments etc.

Froth Pump Structure

Spectral