ZA、ZAO Type Chemical Pumps

Chemical Pumps Parameters

■ Size:25~400mm

■ Capacities Q up to:2600m³/h

■ Heads H up to:250m

■ Operating pressure P up to:2.5MPa

■ Operating temperature T:-20℃~+180℃

■ Centerline support:-20℃~+450℃

Chemical Pumps Features

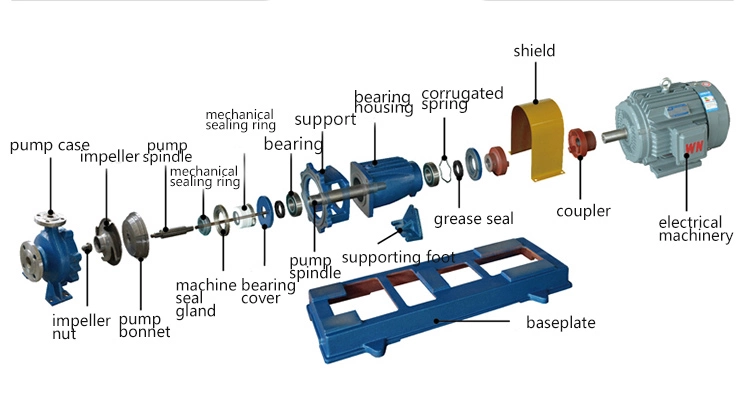

■ It is mainly composed of the pump body, impellers, seal rings, impeller nuts, pump cover, seal parts,

intermediate support, spindle suspended parts and so on.

■ To make it convenient to disassemble, the prolonged coupling is designed, so that it is unnecessary to disassemble the Coupled input &output pipes during check and maintenance, only by disassembling the intermediate coupler of the prolonged coupling, users are able to screw out the rotor part.

■ The shaft seal is mechanical seal generally, use of imported titanium rings and carbide mechanical seals and high-temperature materials, corrosion-resistant, no leakage. The pump is connected with the motor through flexible coupling, the pump rotation direction, from the motor end, is clockwise rotation.

■ Anti-corrosion, wearability, high-temperature resistance, nonaging, high mechanical strength, non-toxic decomposition and wide temperature range of use.

■ This pump can be used to transport sulfuric acid, nitro-hydrochloric acid, strong oxidative and strong.

■ This Acid pump’s biggest advantage is advanced structure, reasonable, strong corrosion-resistance, sealing performance close reliable, stable operation, low noise, long service life.

Chemical Centrifugal Pump Working Condition

■ Mainly applicable to: oil refinery, petrochemical industry, coal processing industry and low temperature engineering, chemical industry, papermaking, pulp industry, sugar industry and general process industry, water supply plant, desalination plant, heating and air conditioning system, power plant, environmental protection engineering, ship and marine industry, etc.

Chemical Process Pump Structure